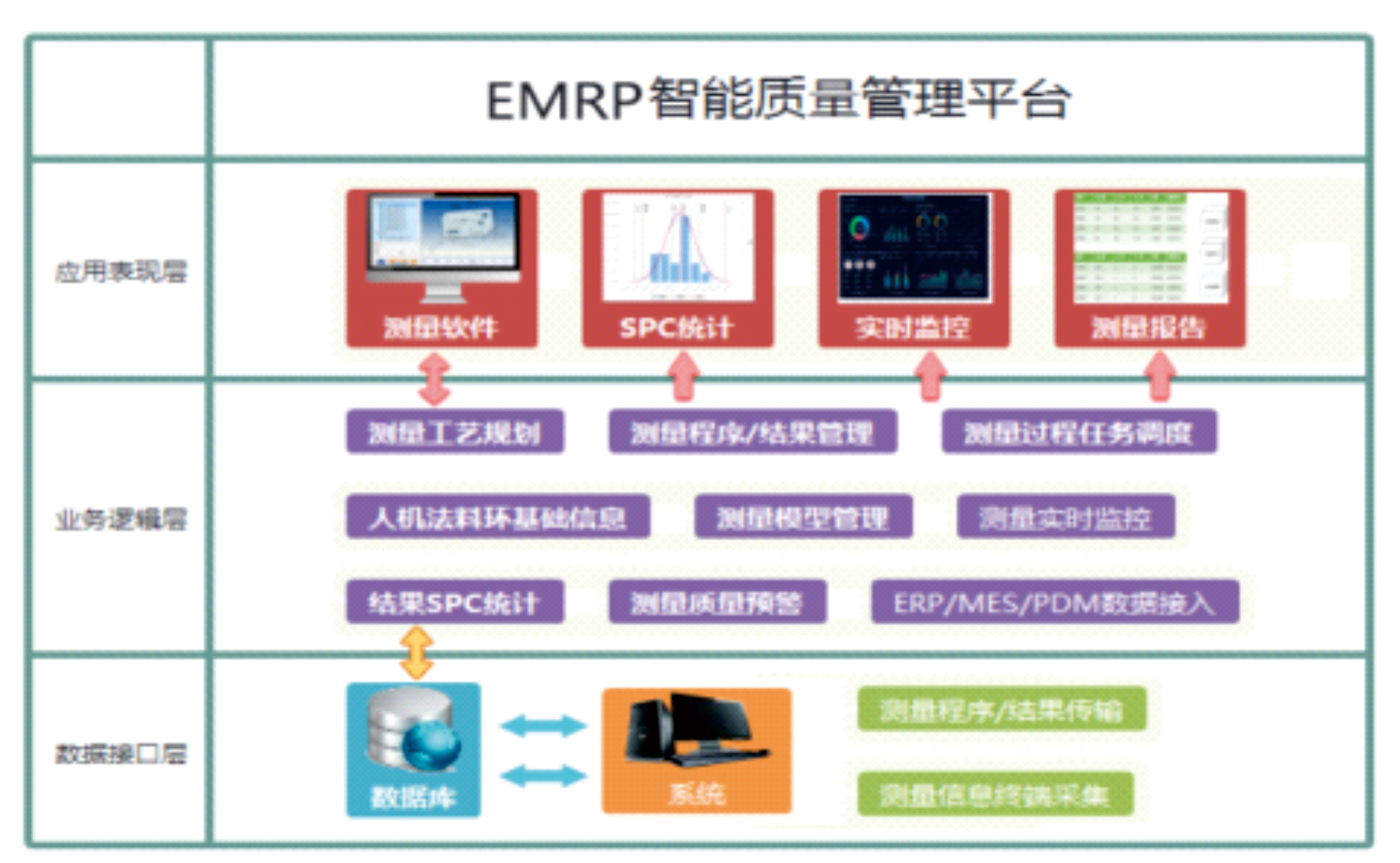

The EMRP intelligent quality management platform integrates multiple resources such as people, machines, methods, materials, and environment in the quality management process, realizes the digitization and networking of product quality management business, and builds a system for the company's product designers, manufacturers, and inspectors to meet the company's product design, product manufacturing, product inspection, product testing, product traceability and other operations to provide quality data support.

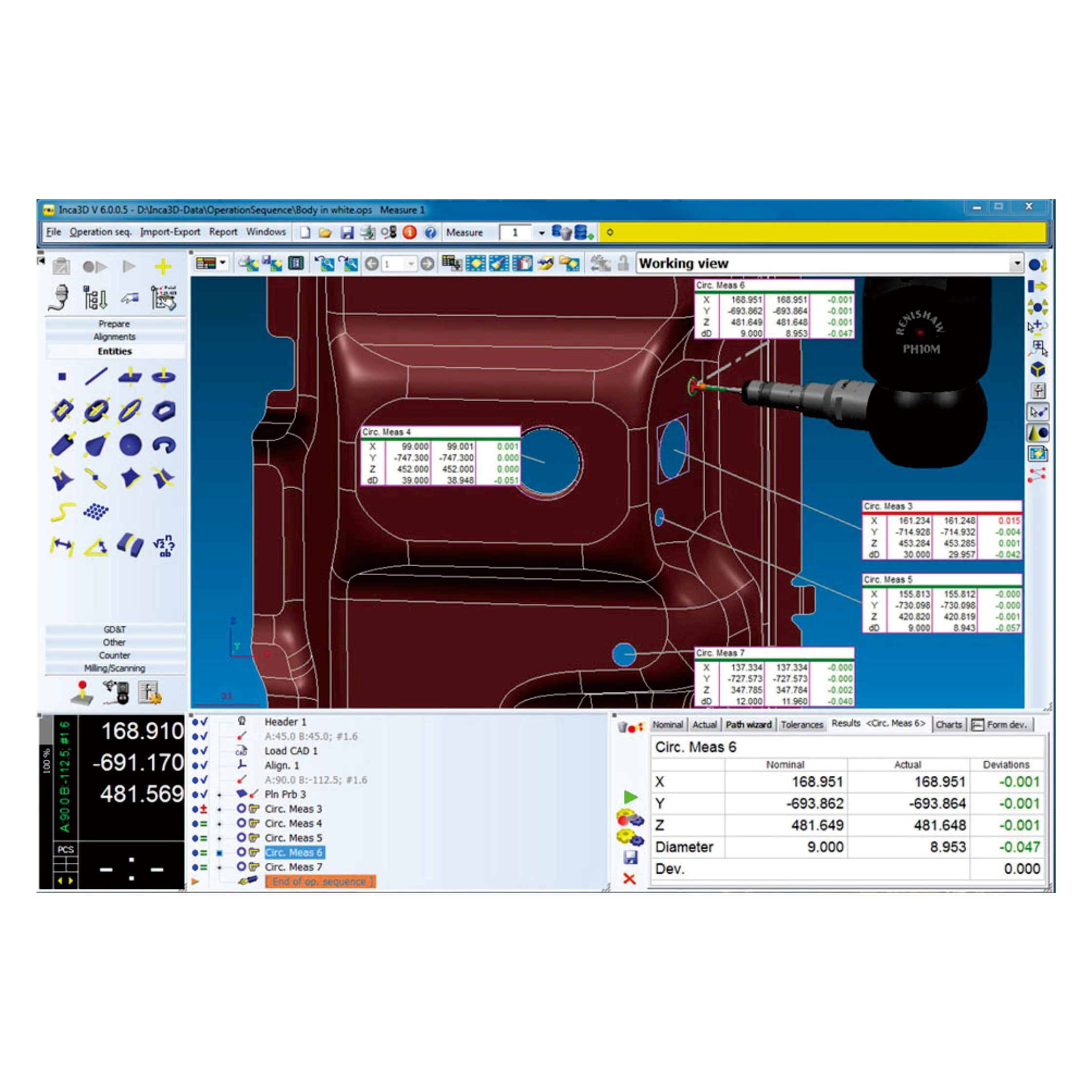

Covering the external and internal properties of products such as geometric quantity, physical and chemical, and length measurement, it supports various manual measuring tools and automatic equipment measurement data collection from various manufacturers; supports self-inspection, first inspection, patrol inspection, outsourcing inspection, process inspection, finished product inspection and other inspection methods. And provide optional modules such as non-conforming product processing, production line quality assembly optimization, and measuring instrument management.

In line with the confidentiality requirements of military enterprises, it has three administrator roles: system administrator, security confidentiality officer, and security auditor, which are independent and mutually restricted.

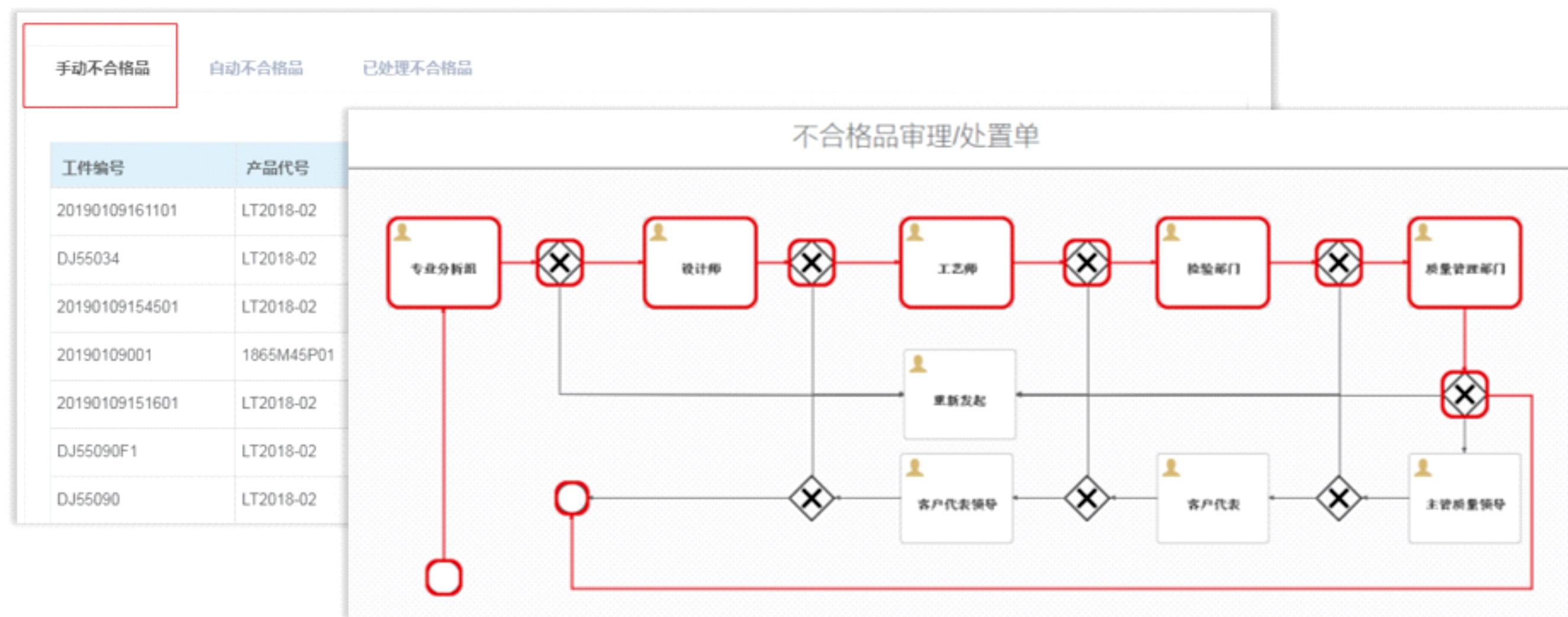

Handling of unqualified products

Handle unqualified measurement items during the inspection process in accordance with GJB9001B or ISO9000 quality management system or customer-defined methods.

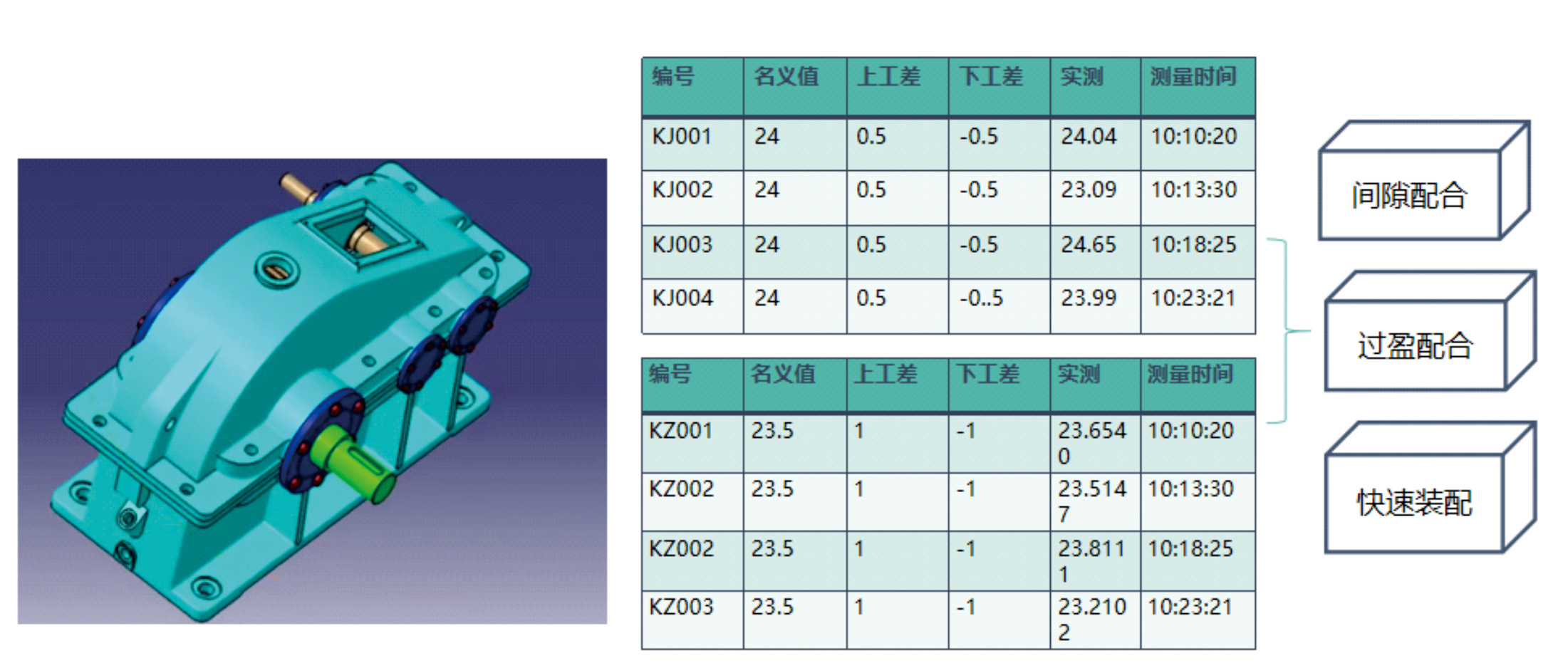

Production line quality assembly optimization

Based on the inspection data of parts in the database, the optimal solution for assembly is automatically arranged through algorithm definition; it improves assembly efficiency, prevents the problem of parts that are qualified in size but cannot be assembled, and eliminates manual errors; the algorithm can be continuously updated and iterated according to customer needs.